MIKRON MILL E 700 U is a powerful and precise 5-axis CNC machining center designed for demanding machining of various materials.

Work table dimensions: 700 x 500 mm

Maximum table load: 500 kg

Number of axes: 5

Maximum spindle speed: 20,000 rpm

Spindle power: 20 kW

Accuracy: ± 0.005 mm

MIKRON MILL E 700 U offers high precision and repeatability, which guarantees consistent machining quality even for demanding tasks. With an accuracy of ± 0.005 mm, this machine is ideal for parts that require maximum precision.

This machine is equipped with advanced features that allow the machining of various materials from aluminum to hardened steels. With five axes, the MIKRON MILL E 700 U provides maximum flexibility when machining complex shapes and contours.

With a maximum spindle speed of 20,000 rpm and a power of 20 kW, the MIKRON MILL E 700 U is designed to maximize productivity. High machining speed reduces cycle time and increases production efficiency.

MIKRON MILL E 700 U is designed with an emphasis on energy efficiency and waste minimization. Advanced control systems optimize energy consumption, thus contributing to greener production.

LEADWELL V-50L is a 4-axis robust and reliable machining center designed for efficient machining of large and demanding parts.

Work table dimensions: 1300 x 600 mm

Maximum table load: 1000 kg

Number of axes: 4

Maximum spindle speed: 10,000 rpm

Spindle power: 15 kW

Accuracy: ± 0.005 mm

The LEADWELL V-50L provides excellent accuracy and stability, which guarantees high quality machining. Accuracy of ± 0.005 mm ensures that even the most demanding tasks will be performed with maximum accuracy and consistency.

This vertical machining center is equipped with a fourth axis, which enables the machining of complex parts with greater flexibility and efficiency. The machine is suitable for machining various materials, from soft metals to hardened steels.

With a maximum spindle speed of 10,000 rpm and an output of 15 kW, this machine is designed for high productivity. Efficient machining and fast cycles contribute to reduced production time and increased output.

Energy efficiency and waste reduction are key features of the LEADWELL V-50L. Advanced control systems optimize energy consumption, which contributes to more sustainable and ecological production.

The SP 280 Y lathe is a highly precise and powerful machine, designed for demanding machining tasks. This versatile lathe is ideal for a wide range of applications, from small parts to large components, with an emphasis on precision and efficiency.

Maximum diameter above the bed: 280 mm

Maximum diameter above the support: 150 mm

Maximum machining length: 750 mm

Spindle diameter: 38 mm

Spindle speed range: 50 - 3000 rpm

Main motor power: 2.2 kW

Accuracy: ± 0.01 mm

The SP 280 Y offers excellent turning precision and stability. With an accuracy of ± 0.01 mm and a spindle speed range of 50 - 3000 rpm, this lathe ensures high machining quality and consistent results even for the most demanding tasks.

This lathe is designed for a wide range of materials including metals, aluminum alloys and plastics. With a maximum diameter above the bed of 280 mm and a maximum machining length of 750 mm, the SP 280 Y is able to process various sizes and shapes of parts.

SP 280 Y is equipped with a powerful 2.2 kW motor, which enables efficient and fast machining. The high spindle speed range and stable performance ensure that the production process is fast and productive, reducing costs and increasing output.

This machine is designed with an emphasis on energy efficiency and waste minimization. Optimized energy consumption management systems contribute to greener and more sustainable production, thereby reducing operating costs and impact on the environment.

Pinnacle VMC 1000 is a high-performance vertical machining center designed for accurate and efficient machining of various materials.

Work table dimensions: 1200 x 600 mm

Maximum table load: 1000 kg

Number of axes: 3

Maximum spindle speed: 10,000 rpm

Spindle power: 11 kW

X/Y/Z feed: 1000/600/600 mm

Rapid feed (X/Y/Z): 30/30 /30 m/min

Accuracy: ± 0.005 mm

The Pinnacle VMC 1000 provides excellent precision and stability during machining. With an accuracy of ± 0.005 mm, it ensures that even the most demanding tasks will be performed with maximum accuracy and consistency. Stable design and high-quality components enable optimal performance even when machining complex parts.

This vertical machining center is designed to handle a wide range of materials, including metals, aluminum alloys and plastics. The large dimensions of the worktable and the high load of the table allow the machining of different sizes of parts and components, which increases the flexibility and efficiency of production.

With a maximum spindle speed of 10,000 rpm and an output of 11 kW, the Pinnacle VMC 1000 is designed for high productivity. Efficient machining and fast cycles contribute to increased output and reduced production costs. A rapid feed of 30 m/min on all axes ensures fast movements and minimal downtime between individual operations.

This machine is designed with energy efficiency and waste minimization in mind. Advanced control systems optimize energy consumption, which contributes to greener and more sustainable production. Energy-saving components and intelligent management ensure efficient use of resources and reduce operating costs.

A high-precision coordinate measuring device (CMM) designed for measuring and checking the dimensions of parts with maximum accuracy. This modern machine combines cutting-edge technology and precise design to ensure thorough quality control in the production process.

Type: Bridge-type CMM (bridge type)

Measuring range (X/Y/Z): 700 x 1000 x 600 mm

Accuracy: 1.8 + L/333 µm

Repeatability: 1.8 µm

Maximum movement speed: 520 mm/s

Sensing system: Touch sensor and laser sensor

Software: Compatible with modern measurement software for 3D measurements and analysis

CORD CMM BRIDGE | ARES provides excellent measurement accuracy, with an accuracy of up to 1.8 µm and a repeatability of 1.8 µm. Thanks to advanced sensing technologies, this machine can perform measurements with high reliability and precision, which is essential for the inspection of critical components in industrial applications.

This CMM machine is designed to measure various types of parts, from small parts to large components. Thanks to the wide measuring range (700 x 1000 x 600 mm) and the possibility of using different sensing systems (touch probes, laser sensors), it is ideal for measuring complex geometries and various materials.

CORD CMM BRIDGE | ARES offers intuitive control and a modern software package that enables easy programming of measurement cycles and analysis of results. The ergonomic design of the machine ensures easy access to the measured parts and comfort for the operator during the entire measurement process.

The device is designed with an emphasis on energy efficiency and minimization of energy consumption. Optimized energy management and long component life contribute to device sustainability and lower operating costs.

MIKRON VCE PRO 600 combines cutting-edge technology and robust design to ensure excellent quality and productivity.

Work table dimensions: 900 x 600 mm

Maximum table load: 600 kg

Number of axes: 3

Maximum spindle speed: 12,000 rpm

Spindle power: 15 kW

Accuracy: ± 0.003 mm

MIKRON VCE PRO 600 provides excellent precision and stability during machining. Accuracy of ± 0.003 mm ensures that even the most demanding tasks will be performed with maximum accuracy and consistency.

This vertical machining center is designed to handle a wide range of materials, including aluminum, steel and alloys. Thanks to its powerful functions, it is suitable for machining complex parts and enables quick tool change for maximum efficiency.

With a maximum spindle speed of 12,000 rpm and a power of 15 kW, the MIKRON VCE PRO 600 is designed for high productivity. Efficient machining and short cycles contribute to increased output and reduced production costs.

This machine is designed with energy efficiency and waste minimization in mind. Advanced control systems optimize energy consumption, which contributes to greener and more sustainable production.

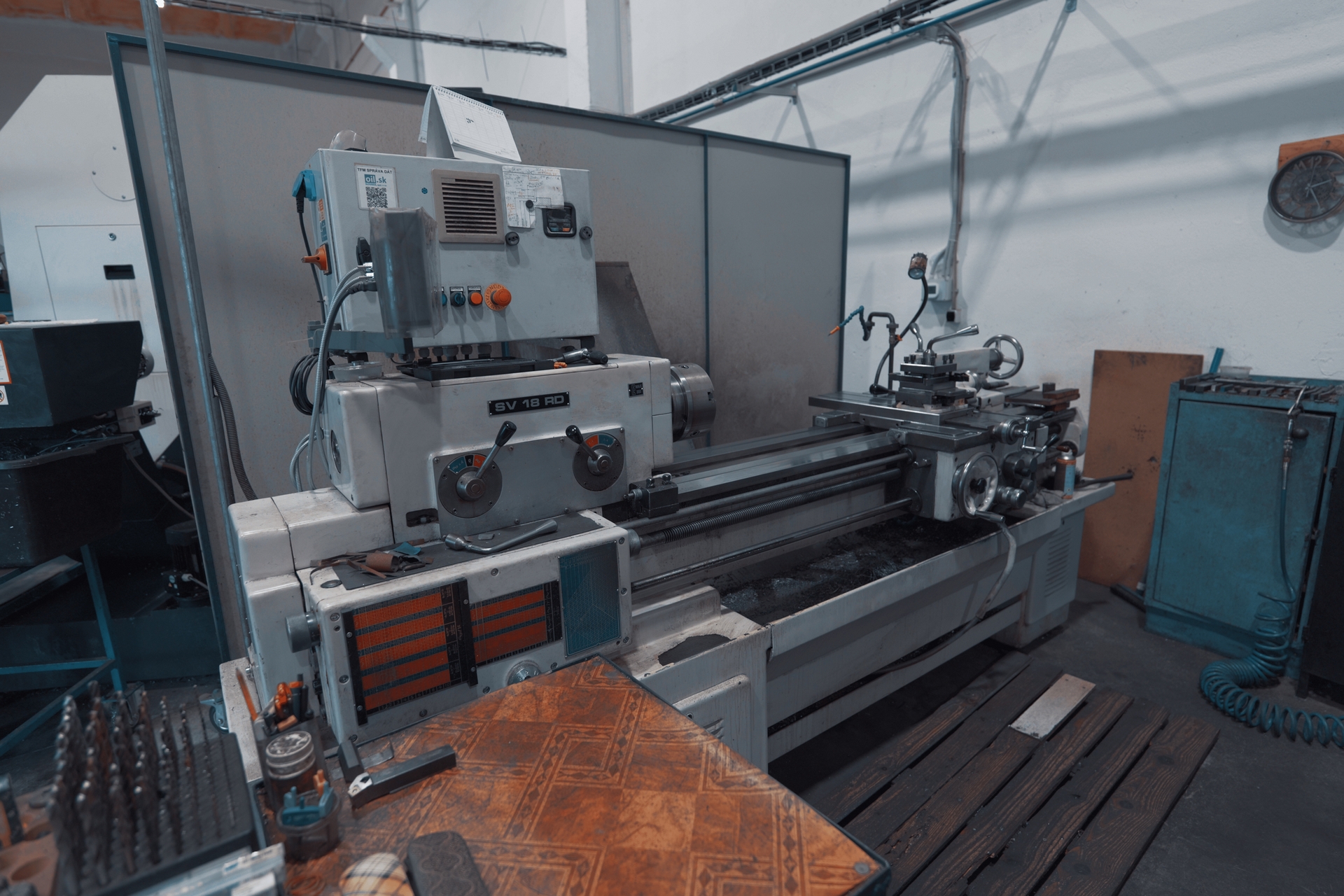

The SV 18 RD lathe is a high-performance and precise machining device, ideal for a wide range of turning applications. This versatile lathe combines robustness, reliability and flexibility to meet the demands of modern workshops and manufacturing.

Maximum diameter above the bed: 380 mm

Maximum diameter above the support: 200 mm

Maximum machining length: 1000 mm

Spindle diameter: 52 mm

Spindle speed range: 20 - 2500 rpm

Main motor power: 5.5 kW

Accuracy: ± 0.01 mm

The SV 18 RD offers excellent precision and stability during turning. Accuracy of ± 0.01 mm ensures that even the most demanding tasks will be performed with maximum accuracy and consistency. Stable design and high-quality components make it possible to achieve optimal performance even when machining complex parts.

This lathe is suitable for machining various materials, including metals and plastics. With a maximum diameter above the bed of 380 mm and a maximum machining length of 1000 mm, the SV 18 RD is capable of processing a wide range of part sizes and shapes, increasing production flexibility and efficiency.

With a main motor power of 5.5 kW and a maximum spindle speed of 2500 rpm, the SV 18 RD is designed for high productivity. This lathe enables fast and efficient machining, which contributes to increasing output and reducing production costs. Effective feed and speed control enables optimization of the production process and reduces downtime.

This machine is designed with energy efficiency and waste minimization in mind. Optimized energy consumption management systems contribute to greener and more sustainable production. Energy-saving components and intelligent management ensure efficient use of resources and reduce operating costs.

Weight of the machine: 4400 kg

Total power input of the machine:: 10.5 kW

Clamping surface of the table: 400 x 1500 mm

Max. grinding length: 1500 mm

Max. grinding width: 470 mm

Spindle speed: 1470, 1720 rpm

Max. workpiece weight: 500 kg